Towards increasing competitiveness with Industry 4.0

During the past two centuries, we have come across three industrial revolutions. From initial drawings and experiments to the conception of mature technological wonders, each revolution was leveraged by introducing disruptive technologies: the steam engine, the development of the modern production line, and the increasing speed of the computer.

Industry 4.0 is the fourth industrial revolution and represents an essential step to reshape the organization and management of the industrial value chain. It combines multidisciplinary technological developments with a symbiosis between novel production methods and information and communication technology. At the core of Industry 4.0 lies the digitalization of manufacturing, the economy, and society.

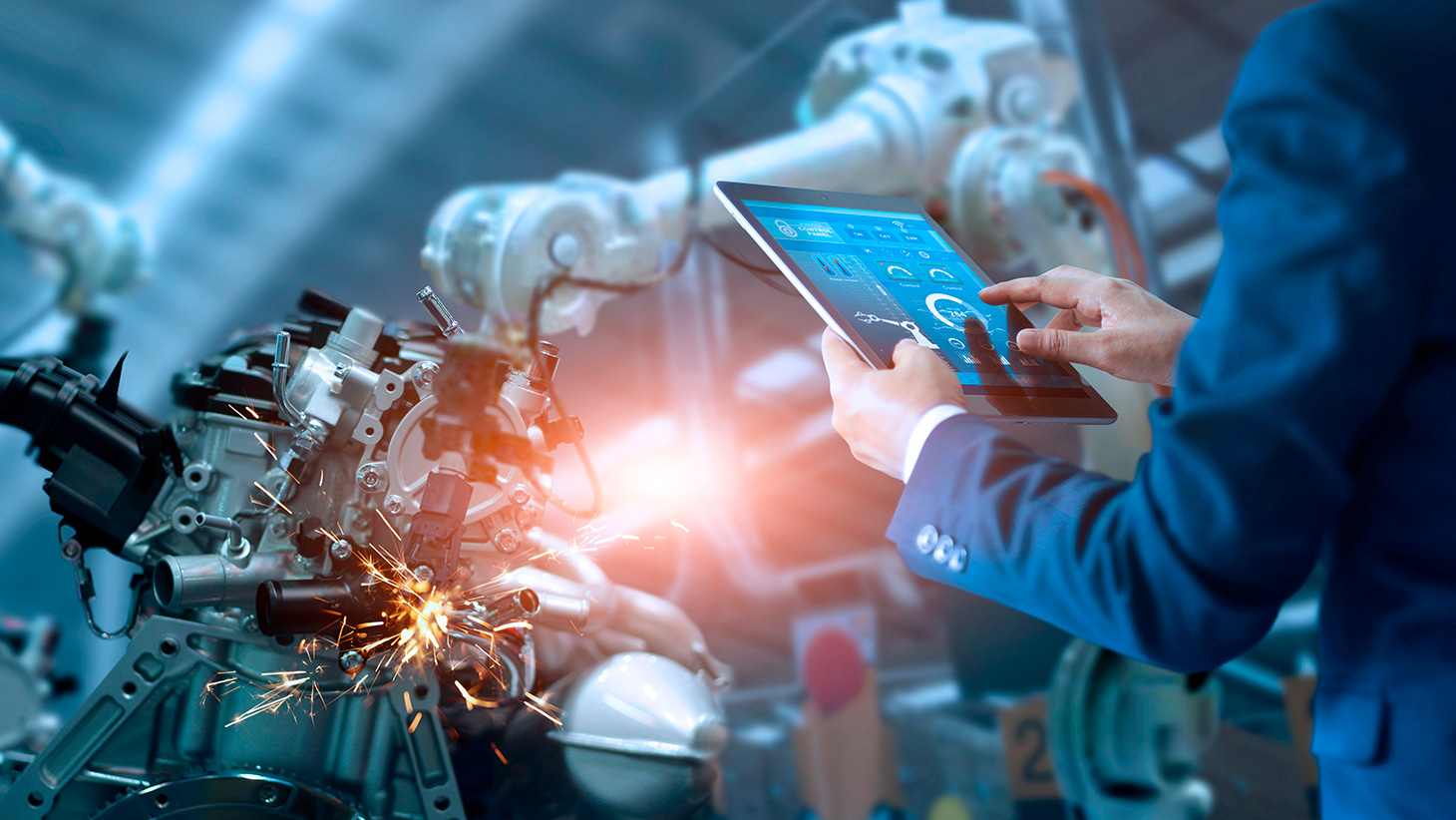

Industry 4.0 relies on Cyber-Physical Systems, intelligent autonomous systems that use sensorization hardware and software with embedded algorithms to monitor and control industrial assets, such as machinery, robots, and vehicles. This digital transformation is connected with enterprise resource planning systems and confers unprecedented levels of monitoring, analytics, and control to the companies adopting this trend.

The range of technologies supporting Industry 4.0 is wide. Data are continuously collected across several sources with unprecedented volume. Big data is analyzed by artificial intelligence and machine learning algorithms delivering insights to improve decision-making to support real-time decisions. The ever-increasing volume of data results in some challenges concerning storage, transmission, and processing. To address these hurdles, Edge computing allows moving computing processes as close to the data source as possible, thus decreasing latency and increasing cybersecurity. Augmented reality is also an emerging trend and can support operators presenting repair or assembly instructions for experienced and novice workers. Collaborative autonomous robots will leverage new human-machine interaction layers since they are designed to interact physically and safely with humans in shared workspaces.

It is worth emphasizing that leveraging robotics and artificial intelligence to shop floors must consider valuing the human factor in the factories of the future. Industry 4.0 allows Humans to work alongside machines cooperatively towards highly productive work methods and processes. Industry 4.0 plays a relevant role in the Portuguese economy and other European economies. To overcome the barriers to Portugal’s competitiveness, we should foster innovation in the Portuguese Industry to ensure it follows digital transformation trends and industrial modernization. An innovative Industry will lead to a stronger Industry, boosting the volume of exportations and increasing the employment in the Portuguese industrial fabric. These actions will increase the sector’s productivity, with an important impact on the national economy and the affirmation of the Portuguese Industry

Autors: Duarte Miguel Folgado, Scientist of the Intelligent Systems Group at Fraunhofer Portugal AICOS.